product description

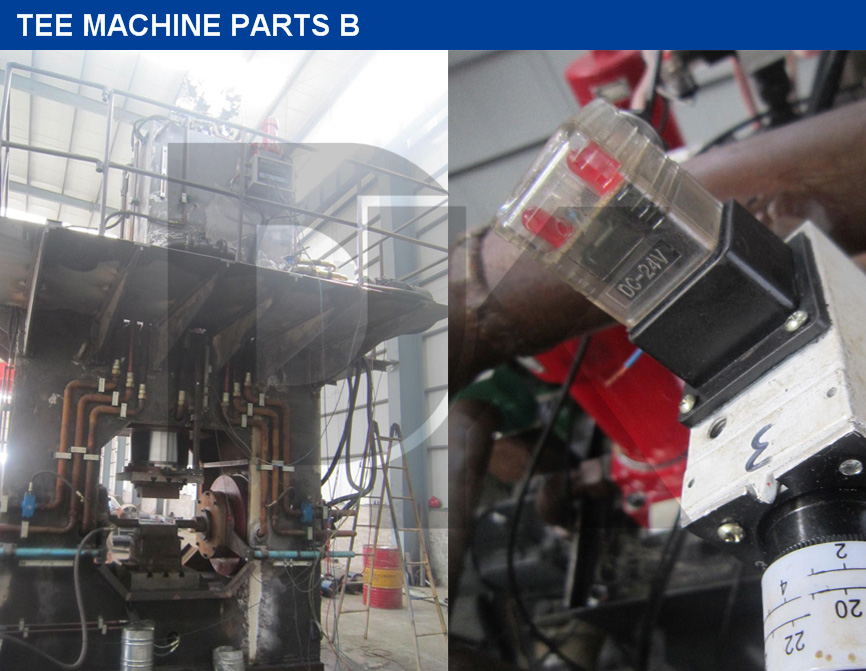

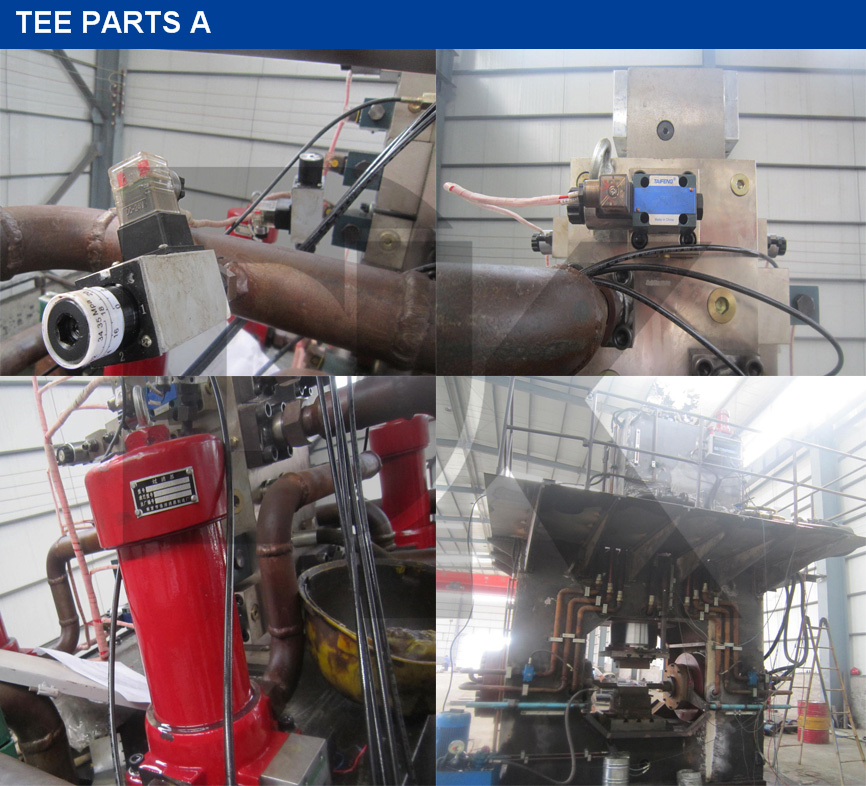

The tee is mainly extruded by the tee hydraulic press.

When the tee machine is in use, it is necessary to extrude the pipe through the upper and lower hydraulic tables and the extrusion tables on both sides, and use the pressure to extrude the pipe into the shape of the mold, and then take it out from the mold. The extruded pipe needs to be cut off. cap, which requires Re-cutting the pipe to complete the entire processing process is very cumbersome, time-consuming and labor-intensive. In the existing tee machine, a high-pressure water gun is installed at one end of the extrusion table. By injecting liquid into the pipe, the pressure is continuously increased to cooperate with the hydraulic table to complete the extrusion of the pipe. After extrusion, the moisture inside the pipe out of the pipe.The outlet flows out and flows to the extrusion table, which leads to the poor working environment. There are many power-consuming components when using the tee machine. necessary loss.

| Model Parameter | DK80A | DK 100A | DK 150B | DK 200A | DK 250B | DK 300B | DK 400A | |

| Processing Size | Inch | 1/2"-3" | 1/2"-4" | 2"-6" | 2"-8" | 4"-10" | 5"-12" | 6"-16" |

| Clamping Force | KN | 4500 | 6000 | 8000 | 15000 | 20000 | 25000 | 28000 |

| Pushing Force | KN | 4000×2 | 5000×2 | 7000×2 | 12000×2 | 18000×2 | 20000×2 | 25000×2 |

| Working Pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Power | KW | ~55 | ~55 | ~90 | ~110 | ~135 | ~276 | ~295 |

| Table Size | mm | 660*660 | 660*660 | 1000*1000 | 1100*1100 | 1600*1600 | 1650*1800 | 1700*1800 |

| Weight | T | ~22 | ~28 | ~56 | ~70 | ~120 | ~220 | ~280 |

Add.: Cangzhou City, Hebei Province, China

Tel.: +86 317 8969 768

Mob.: +86 186 3076 4242

Fax: +86 317 8969 768

WhatsApp: +86 186 3076 4242

WeChat: +86 186 3076 4242

Skype: live:manager_11748

E-mail: manager@tyfittingsmachine.com

NAVIGATION